Modular Cabinet System for ULTIMATE shop ORGANIZATION

I love toys…. I mean tools. To quote a friend in the trades “If buying cool tools isn’t part of this career then what’s the point?”

Like most of us, I don’t have unlimited shop space. In fact for about 3 years I fit my ENTIRE SHOP in a 6x12 CARGO TRAILER. I would then set up outside or in a customer’s garage. I still made great things.

How did I organize all of my tools to maximize space? I went modular.

I make no secret that I am a fan of Ron Paulk over at the SMART Woodshop. The idea for the modular shop cabinets i’m about to show you came from him and the need for tradesmen to fit a lot of tools in a Van or Trailer AND be able to quickly access them.

Drawers LOTS of Drawers

My entire system is based on a standardized drawer size. This isn’t anything unique. Festool Systainers, Dewalt T-Stak, Milwaukee Packout, etc. All these tool box systems follow the same idea. The foot print (the length and width) is identical and the heights are multiples of a standard. They then nest or latch together.

These tool box systems are great the issue is accessibility, inevitably you will need the tool at the bottom of the stack. This is why many people build cabinets with drawer slides to solve this issue.

That’s essentially what I did. I sized the cabinet and drawers around a standard. At the time I wanted my Socket set case to fit in the cabinet it was just a little bit bigger than the Systainer and T-Stak so that gave me the flexibility to not be locked into one type of manufactured modular tool box.

My drawers allow me to use a manufactured tool box if I chose OR build out a custom drawer for non-cased tools, parts, or just to maximize space.

Drawer Slides can get expensive so We use DADOS for Drawer Slides

If you look closely at the workbench base you can see the dados. I cut 3/4” Dados and use 1/2” Plywood for the base of the drawers. This allows the drawers to slide easily and use a passive latch that I’ll show you in the video below.

I just did a quick count and in my shop (currently) I could have a maximum of 104 drawers in my modular cabinets. Assuming I used 18” soft close drawer slides at $17.90 a piece that would potentially cost $1861.60 in drawer slides alone! No thanks.

Now obviously I don’t have that many drawers because many are double or triple height but if I were to use a manufactured drawer slide I would be limited on where drawers could go.

Buy routing Dados into the sides of my cabinets and using the bottom of the drawer for the runners I save a lot of money and can easily size drawers, space them, and rearrange. PLUS since there is no hardware I can take them out easily and use them as a stand alone tool box.

Make these yourself. It’s super easy with the jigs shown in the video!

Size these modular cabinets to your unique needs.

Here are my standard dimensions.

Cabinet Sides are built with 3/4” (18mm) plywood. They finished cabinets are 20” wide and 18” deep. Height is determined by the application.

Cabinet Dados are 3/4” wide and 3/8” deep. I start the first dado 1” from the bottom of the cabinet sides. This allows clearance for the 3/4” spreader on the bottom. I space the dados 3” apart from the top of the dado to the bottom of the next dado. I determined this size based on my router base. It seemed like a good size and made my jig making easy so I went with it

Cabinet Backs - I use 1/2 plywood/OSB or whatever other scrap I have to add a cabinet back. This makes my finished cabinet 20” wide and 18 1/2” deep.

Drawer bases - My 1/2” plywood bases are 18” deep and 19 1/4” wide.

Drawer Fronts and Sides. My base height for drawer fronts and sides is 3”. The length of the front and back is 17 1/4 and the length of the sides is 18”

Assembly - Glue and staples

Passive Drawer Latches - Cut a 1/2” x 1” notch in the front of the drawer rail. In the dados glue and nail a 1/4” x 3/8” x 1” piece of wood in the cabinet. This makes an easy passive latch. The Video Shows this in more detail.

Whether you build your drawers to the diminsions I gave or have a different measurement in mind, I highly encourage you to find a standardized system for your shop drawers. This will give you endless flexiblity in organizing, arranging, and rearranging your shop space to suit your needs.

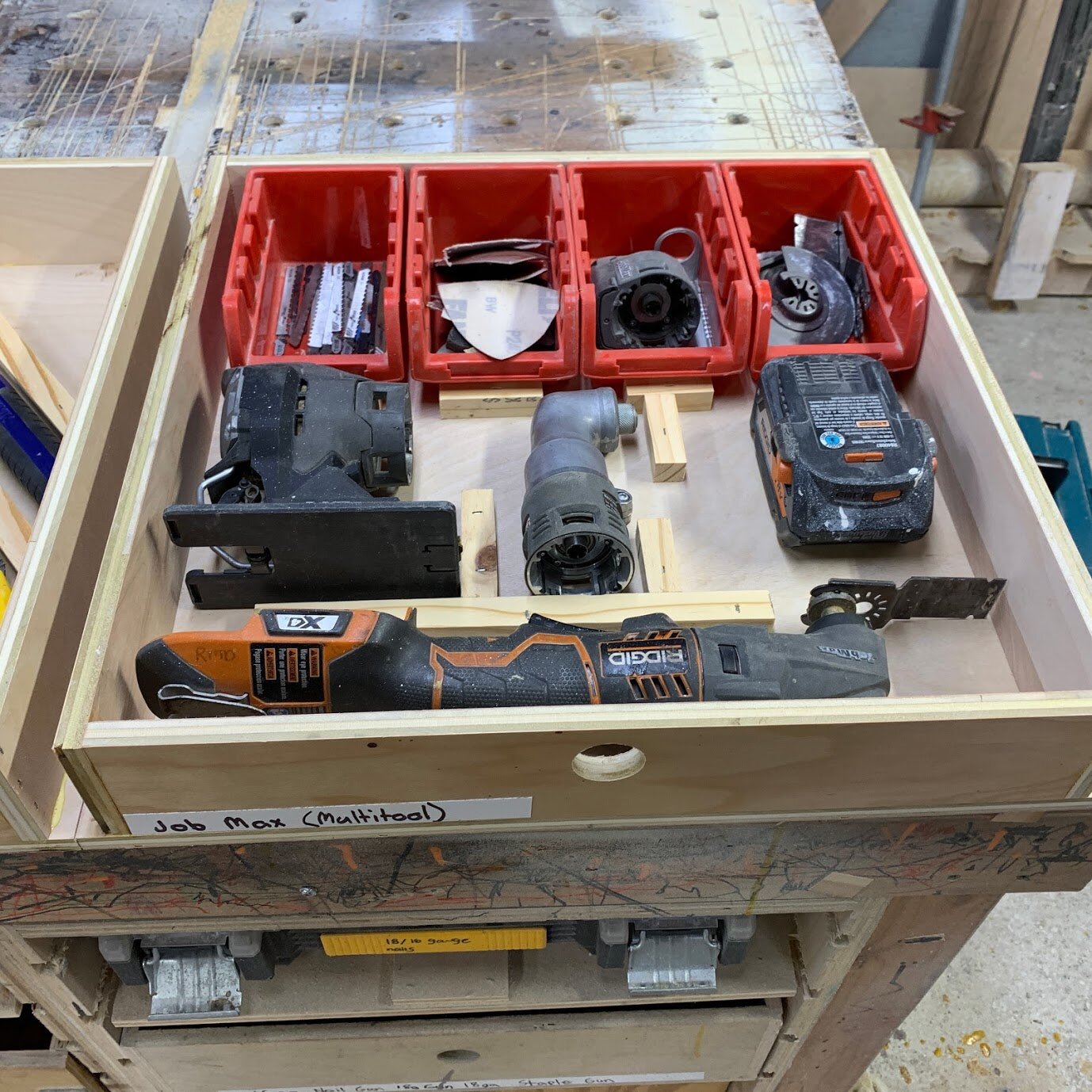

Here are some final photos to show some of the ways I’ve built out my drawers.

My Ridgid JobMax is my Multitool but it also has interchangeable heads for doing right-angle drilling and can turn into a jigsaw.

Sometimes in sizing my cabinets to the height I need leaves an odd size drawer. So I used the shallow drawer spot to organize all my driver bits.

This drawer is 2 units tall and holds my Makita Router and Accessories. The Router came in its own systainer but I felt that it is quicker to access and takes up less space in it’s own drawer.

Even though my Festool Rotex came in a Systainer I found it was easier to access and took up less space to build a custom drawer to hold it and all the paper. You can see just above that I chose to leave another tool in its case and it sits in a drawer.

Because there’s no hardware I can easily pull the entire drawer out and take it to where I’m working. This is my drawer installation tool kit.

If you found this article useful, please consider supporting us financially.

You can also use our Tool Kit page to make purchases with our affiliate links